Hook-type blasting machines

- blasting of simple and complicated parts separately and in group

- uniform blasting: blasting turbines on fixed block and current hook turning nad movement

- protective wearresistant lining of cabin and blasting turbines

- automatical separation of abrasive material

- suction + automatic filtration

- operating PLC by colored touch screen

These machines are ensured for blasting of every simple and complicated parts which are hookable.

The blasted parts are hanged separatelly or in group on hook, which is rotated and moved in front of blasting turbines. These movements together with thrown abrasive material from blasting turbines ensure uniform blasting of every parts.

The machine is equipped with recuperation of abrasive material, which ensures its cleaning.

Whole machine is sealed against leakege of abrasive material out from cabin. The cabin and recuperation is connected to suction with automatic filtration.

Basic equipment:

- Operating PLC by colored touch screen

- Going of hook inside and out by chains driven by gearboxes

- Y – rail with two hooks

- Blasting turbines with parts made from wearresistant hardened manganese cast iron.

- Protective wearresistant lining of cabin.

- Cleaning (separation) of abrasive material

- Suction and filtration arrangement

| Machine type |

TZ 2-5,5/11-16 |

TZ 3-5,5/11-21 |

TZ 3-7,5/16-21 |

| Max. detail diameter |

1100 |

1100 |

1600 |

| Max. detail height |

1600 |

2100 |

2100 |

| Load capacity |

500 (1000) |

500 (1000) |

1000 |

| Number of blasting wheels |

2 |

3 |

3 |

| Power of blasting wheel |

5,5/7,5 |

5,5/7,5 |

7,5/12 |

| Turbine revolutions |

2900 |

2900 |

2900 |

| Total power (incl. filter) |

18/22 |

25/31 |

38/52 |

| Filter capacity (m3/hour) |

4000 |

5000 |

6500 |

| Machine type |

TZ 3-7,5/20-23 |

TZ 4-7,5/20-32 |

TZ 4-7,5/25-35 |

| Max. detail diameter |

2000 |

2000 |

2500 |

| Max. detail height |

2300 |

3200 |

3500 |

| Load capacity |

1000 |

1000 (1400) |

1000 (1400) |

| Number of blasting wheels |

3 |

4 |

4 |

| Power of blasting wheel |

7,5/12 |

7,5/12 |

7,5/12 |

| Turbine revolutions |

2900 |

2900 |

2900 |

| Total power (incl. filter) |

38/52 |

45/59 |

45/59 |

| Filter capacity (m3/hour) |

7500 |

10000 |

10000 |

Our sales department will consult your qeustions, enquiries, orders. Vote one from possibilities.

- Call salles representative tel. (+420) 776 286 602

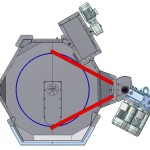

New hook-type blasting machine

New generation of blasting style

- blasting of simple and complicated parts separately and in group

- higher efficiency and shorter blasting time: hook turning + moving block with blasting turbines / max. angel 55° – setting according with blasted part

- saving of electrical energy

- protective wearresistant lining of cabin and blasting turbines

- automatical separation of abrasive material

- suction + automatic filtration

- operating PLC by colored touch screen

The novelty of this type is exchange of parts blasting, during blasting cycle the hook turns to roght or to left and in the same time the block with blasting turbines is moving in set angle, max. 55°. This moving is driven by servomotor, it enables setting of space where the abrasive material is thrown according with dimensions and proportions of parts. One from lot of possibilities is setting of blasting directly to critical places, this is especially advantageous for blasting of complicated parts. This solution increases blasting efficieny and reduces blasting time.

In this type there are used gearboxes with higher efficiency what brings lower power compsumption.

| Machine type |

TZNZ 2-5,5/11-16 |

TZNZ 3-5,5/11-21 |

TZNZ 3-7,5/16-23 |

TZNZ 4-7,5/16-28 |

| Max. detail diameter |

1100 |

1100 |

1600 |

1600 |

| Max. detail height |

1600 |

2100 |

2300 |

2800 |

| Load capacity |

500 (1000) |

500 (1000) |

1000 |

1000 |

| Number of blasting wheels |

2 |

3 |

3 |

4 |

| Power of blasting wheel |

5,5/7,5 |

5,5/7,5 |

7,5/12 |

7,5/12 |

| Turbine revolutions |

2900 |

2900 |

2900 |

2900 |

| Total power (incl. filter) |

18/22 |

25/31 |

38/52 |

45/62 |

| Filter capacity |

4000 |

5000 |

6500 |

7500 |

Our sales department will consult your qeustions, enquiries, orders. Vote one from possibilities.

- Call sales representative: (+420) 776 286 602

New hook-type blasting machine with table

New generation of blasting style with posibility of part putting on turning table

- this solution offers advantages of new style blasting with posilbility of parts putting on the table into cabin

- it is suitable for bulky parts

- blasting of simple and complicated parts separately and in group on hook

- higher efficiency and shorter blasting time: hook turning + moving block with blasting turbines / max. angel 55° – setting according with blasted part

- saving of electrical energy

- protective wearresistant lining of cabin and blasting turbines

- automatical separation of abrasive material

- suction + automatic filtration

- operating PLC by colored touch screen

The novelty of this type is exchange of parts blasting, during blasting cycle the hook turns to roght or to left and in the same time the block with blasting turbines is moving in set angle, max. 55°. This moving is driven by servomotor, it enables setting of space where the abrasive material is thrown according with dimensions and proportions of parts. One from lot of possibilities is setting of blasting directly to critical places, this is especially advantageous for blasting of complicated parts. This solution increases blasting efficieny and reduces blasting time.

In this type there are used gearboxes with higher efficiency what brings lower power compsumption.

| Machine type |

TZZS 2-5,5/11-16 |

TZZS 3-5,5/11-21 |

TZZS 3-7,5/16-23 |

TZZS 4-7,5/16-28 |

| Max. detail diameter |

1100 |

1100 |

1600 |

1600 |

| Max. detail height |

1600 |

2100 |

2300 |

2800 |

| Load capacity |

500 (1000) |

500 (1000) |

1000 |

1000 |

| Number of blasting wheels |

2 |

3 |

3 |

4 |

| Power of blasting wheel |

5,5/7,5 |

5,5/7,5 |

7,5/12 |

7,5/12 |

| Turbine revolutions |

2900 |

2900 |

2900 |

2900 |

| Total power (incl. filter) |

18/22 |

25/31 |

38/52 |

45/62 |

| Filter capacity |

4000 |

5000 |

6500 |

7500 |

Our sales department will consult your qeustions, enquiries, orders. Vote one from possibilities.

- Call sales representative: (+420) 776 286 602

Table blasting machines

In this machine there are the parts put on the table and the upper and sides are blasted. TZS 1-5,5/600 TZS 1-5,5/1100 TZS 2-7,5/1600-1000 600mm 1100mm 1600mm 400mm 500mm 1000mm 300kg 500kg 1000kg 1 1 2 5,5 kW 5,5/7,5kW 7,5/12 kW 2900 2900 2900 12 kW 15/17kW 22/31kW 1500 2500 5000

Our sales department will consult your qeustions, enquiries, orders. Vote one from possibilities.

MACHINE TYPE

Max. detail diameter

Max. detail height

Load capacity

Number of blasting turbines

Power of blasting turbine

Turbine revolution

Total power (incl. filter)

Filter capacity

Operating PLC by coloured touch screenStandard equipment:

Tumbling machine

- blasting of forgings, castings small parts

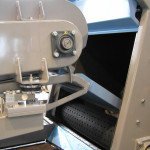

- endless wearresistant rubber belt with bars for careful rolling of parts or steel belt made from manganese segments

- wearresistant lining of changer and blasting turbines

- automatical separation of abrasive material

- suction + automatic filtration

- operating PLC by colored touch screen

- possibility to equip with skip and unloading conveyor

Tumbling blasting machines are suitable for blasting of forgings and small parts. Parts are rolled on rubber belt and abrasive material is thrown on their surface. The turbine is built-in such a way, so that the stream of blasting medium blasts the whole surface of partsuniformly. It is possible to equip skip and unloading conveyor for simplier manipulation according with customerś wishes.

| MACHINE TYPE |

TZB 1-5,5/700 |

TZB 2-7,5/1100-1000 |

TZB 2-7,5/1200-1100 Mn |

| Max. weigt of load |

350 kg |

800 kg |

1000 kg |

| Max. volume of load |

165 dm3 |

425 dm3 |

475 dm3 |

| Max. weight of one part |

15 kg |

20 kg |

40 kg |

| Max. dimension of part |

345 mm |

380 mm |

450 mm |

| Dimensions of blasting chamber |

Ø720 x 800 mm |

Ø1000 x 1100 mm |

Ø1100 x 1200 mm |

| Number of blasting turbines |

1 |

2 |

2 |

| Power of blasting turbine |

5,5 / 7,5 kW |

7,5/12 kW |

7,5/12 kW |

| Turbine revolution |

2900 |

2900 |

2900 |

| Total power (incl. filter) |

10/12 kW |

30/39 kW |

34/42kW |

| Filter capacity |

4000 |

6000 |

7000 |

Standard equipment:

- Opearting PLC by coloured touch screen

- Edless wearresistant rubber belt for care turning of parts or steel belt from manganese plates

- Unloading by belt turning back

- Operating of door by chains

- Blasting wheels with blades a linings from hardened wearresistant cast iron

- Protective linings of blasting cabin

- Separation of abrasive materisl

- Suction + automatic filtration

Our sales department will consult your qeustions, enquiries, orders. Vote one from possibilities.

- Call sales representative tel. (+420) 776 286 602

Continuous blasting machine

Continuous blasting machines are designed for blasting of plates profiles, longer welded parts and smaller parts put on the sieve. The parts are contiually transported on roller or belt conveyor. Blasting turbines are established for blasting of whole part surface. Main advantage -it is not needed base hole for machine, just flat floor. TZNP 4-7,5/1×0,6 TZNP 4-7,5/1,5×0,13 TZNP 4-7,5/1,5×0,6 1000mm 1500mm 1500mm 600mm 130mm 600m 4 4 4 7,5/12 kW 7,5/12 kW 7,5/12 kW 2900 2900 2900 52/70kW 52/70kW 52/70kW 6500 7500 7500 Standard equipment:

Our sales department will consult your qeustions, enquiries, orders. Vote one from possibilities.

MACHINE TYPE

Max. part width

Max. part height

load capacity of conveyor

700kg/m

700kg/m

700kg/m

Number of blasting turbines

Power of blasting turbine

Turbine revolutions

Total power (incl. filter)

Filter capacity