Tumbling machine

- blasting of forgings, castings small parts

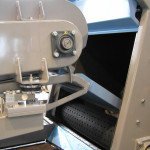

- endless wearresistant rubber belt with bars for careful rolling of parts or steel belt made from manganese segments

- wearresistant lining of changer and blasting turbines

- automatical separation of abrasive material

- suction + automatic filtration

- operating PLC by colored touch screen

- possibility to equip with skip and unloading conveyor

Tumbling blasting machines are suitable for blasting of forgings and small parts. Parts are rolled on rubber belt and abrasive material is thrown on their surface. The turbine is built-in such a way, so that the stream of blasting medium blasts the whole surface of partsuniformly. It is possible to equip skip and unloading conveyor for simplier manipulation according with customerś wishes.

| MACHINE TYPE |

TZB 1-5,5/700 |

TZB 2-7,5/1100-1000 |

TZB 2-7,5/1200-1100 Mn |

| Max. weigt of load |

350 kg |

800 kg |

1000 kg |

| Max. volume of load |

165 dm3 |

425 dm3 |

475 dm3 |

| Max. weight of one part |

15 kg |

20 kg |

40 kg |

| Max. dimension of part |

345 mm |

380 mm |

450 mm |

| Dimensions of blasting chamber |

Ø720 x 800 mm |

Ø1000 x 1100 mm |

Ø1100 x 1200 mm |

| Number of blasting turbines |

1 |

2 |

2 |

| Power of blasting turbine |

5,5 / 7,5 kW |

7,5/12 kW |

7,5/12 kW |

| Turbine revolution |

2900 |

2900 |

2900 |

| Total power (incl. filter) |

10/12 kW |

30/39 kW |

34/42kW |

| Filter capacity |

4000 |

6000 |

7000 |

Standard equipment:

- Opearting PLC by coloured touch screen

- Edless wearresistant rubber belt for care turning of parts or steel belt from manganese plates

- Unloading by belt turning back

- Operating of door by chains

- Blasting wheels with blades a linings from hardened wearresistant cast iron

- Protective linings of blasting cabin

- Separation of abrasive materisl

- Suction + automatic filtration

Our sales department will consult your qeustions, enquiries, orders. Vote one from possibilities.

- Call sales representative tel. (+420) 776 286 602